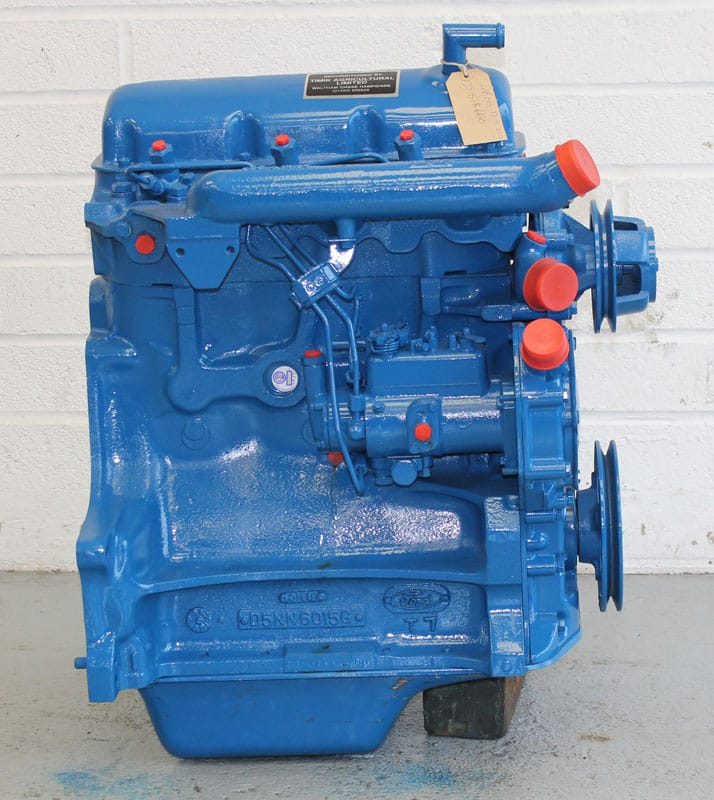

Re-manufactured Ford 4600 Diesel Tractor Engine

Timik Engines specialises in re-manufacturing premium-quality diesel tractor engines at our dedicated facility near Southampton, Hampshire.

Our highly skilled technicians rebuild every engine to the stringent standards required by the Federation of Engine Re-manufacturers, complying fully with the British Standard BSI AU 257:2002.

History and Legacy of the Ford 4600 Engine

The Ford 4600 diesel engine, first produced in the mid-1970s, quickly established itself as one of the most dependable and efficient agricultural power units available.

Renowned for its robustness, reliability, and ease of maintenance, the 4600 remains popular among farmers and agricultural engineers to this day.

Its straightforward design ensures fewer complexities, resulting in reduced downtime and cost-effective operation.

Its enduring appeal is primarily due to its solid engineering, durable construction, and exceptional performance in a wide range of farming applications.

Whether it’s heavy-duty ploughing or routine yard work, the Ford 4600 consistently delivers impressive torque and power with remarkable fuel efficiency.

Core Features of the Ford 4600 Engine:

- 3-cylinder diesel engine

- Displacement: 3.3 litres

- Robust cast iron block construction

- Direct fuel injection system

- Efficient power output ideal for multiple agricultural applications

- Simple, low-maintenance design

Re-manufacturing Process Overview

Core Parts Restoration

- Engine Block: Precisely bored back to standard specification and fitted with new liners.

- Cylinder Head: Fully re-manufactured; valve seats expertly re-cut, with new valves fitted as necessary.

- Crankshaft: Ground to precise tolerances ensuring optimal engine balance and performance.

- Fuel Injection Equipment: Thoroughly remanufactured, including injection pump and injectors, to restore original factory performance.

- Turbocharger: If applicable, fully re-manufactured and carefully balanced.

Engine Re-assembly

Every engine is meticulously rebuilt in our clean, controlled environment workshop:

- New pistons and piston rings

- All new bearings (main, big-end, and camshaft bearings)

- Replacement oil pump and water pump

- Comprehensive new gasket set

- All other components thoroughly inspected and replaced if necessary

Once assembled, each engine undergoes rigorous dynamometer testing to verify power, torque, oil pressure, and coolant flow, ensuring complete reliability.

Engines are finished with a high-quality paint, ready for immediate installation.

Ordering Information and Core Exchange

All Ford 4600 engines from Timik Engines are custom-built to order, tailored specifically to meet your precise needs.

Pricing is based upon the customer supplying an exchange unit. Should an appropriate exchange unit not be available in our stock, your existing engine will need to be provided for re-manufacture.

Please contact us with your fuel injection pump number, and the machine model it is fitted to so can advise if we can offer an exchange unit or will require your own engine to rebuild.