Remanufactured engines have become an increasingly popular choice for various industries worldwide, offering a cost-effective alternative to new engines without compromising on performance, efficiency, or reliability. Two leading brands in the world of remanufactured engines are Ford and Perkins, both of which are renowned for their durable, high-quality, and powerful engines. By opting for remanufactured Ford and Perkins engines, businesses in agriculture, construction, and mining can significantly reduce their operational costs and contribute to a more sustainable economy.

In this blog article, we aim to provide an in-depth understanding of the advantages associated with using remanufactured Ford and Perkins engines and their contributions to the success of global industries. Additionally, we will explore the process of reconditioning engines, emphasising the stringent quality control and performance testing protocols that ensure these engines meet the highest standards of reliability and efficiency.

With a focus on both the UK market and the burgeoning export markets in Africa and mainland Europe, this article will provide a comprehensive perspective on the role of remanufactured engines in supporting a sustainable and profitable future for industries worldwide.

The use of remanufactured engines has been on the rise in recent years, driven by factors such as increasing pressure on businesses to reduce costs and operate more sustainably. remanufactured engines offer numerous advantages compared to their brand-new counterparts, from lower upfront costs and reduced environmental impact to easier availability in overseas markets. As experts in the supply of remanufactured Ford and Perkins engines, as well as spares for all makes of tractors and equipment, we aim to provide our audience with valuable insights into the benefits of these engines and their role in driving the success of businesses worldwide.

So, if you’re keen to explore the world of remanufactured Ford and Perkins engines, join us as we delve into the advantages, the reconditioning process, and the far-reaching impact of these engines on industries operating not just in the UK, but also across Africa and mainland Europe.

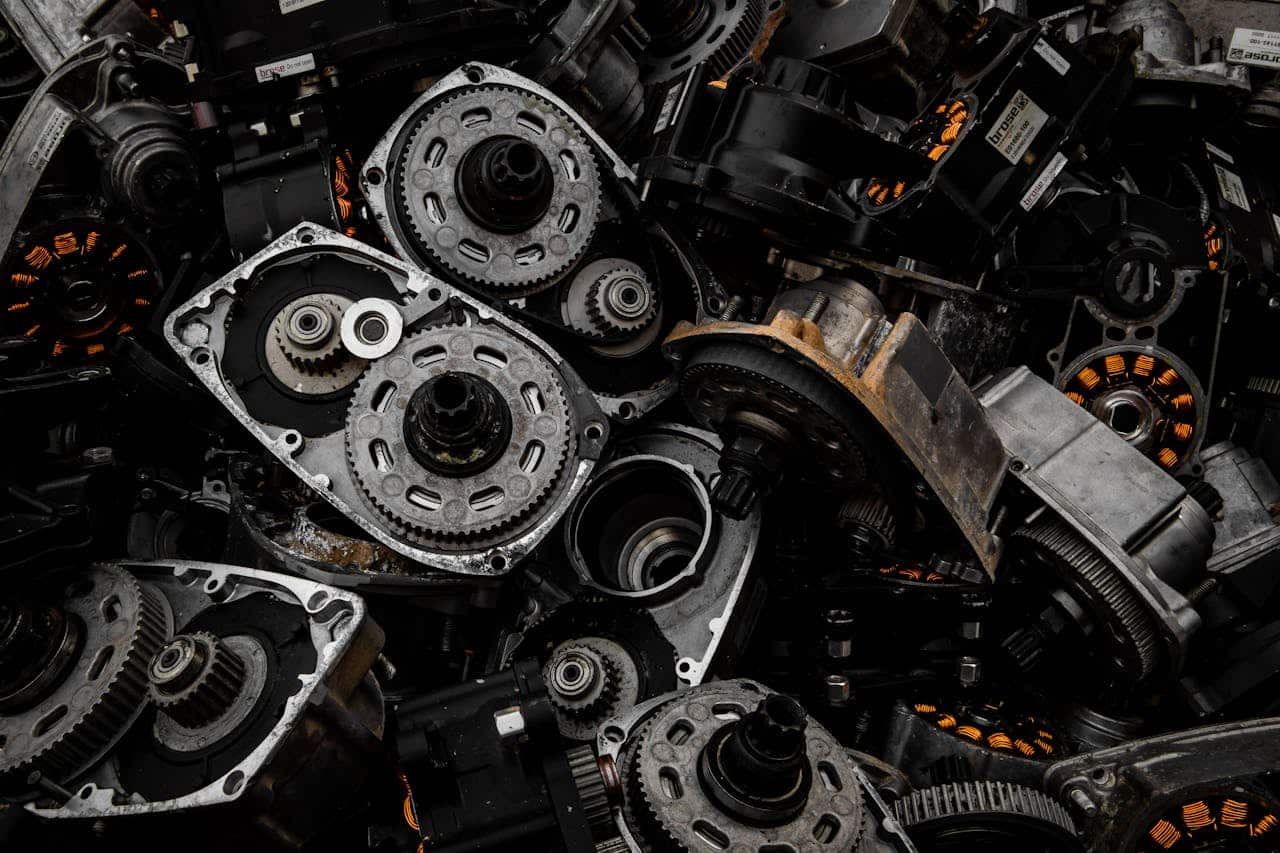

remanufactured Ford and Perkins engines have become increasingly popular in various industries due to the numerous benefits they offer when compared to brand-new engines. Some of these advantages include:

Many people use remanufacturing and reconditioning as equivalent terms, but they have their differences. Reconditioned engines are simply used engines that have been disassembled, cleaned, and had any worn or broken parts replaced before being put back together. Meanwhile, remanufactured engines are units that have been returned to the manufacturer’s original factory specifications.

While remanufactured engines are essentially “as good as new” and provide optimal levels of performance, reconditioned engines may still have some worn components.

To fully appreciate the value of remanufactured Ford and Perkins engines, it’s essential to understand the reconditioning process. This process involves several crucial steps to ensure the engine’s performance and reliability:

remanufactured Ford and Perkins engines play a significant role in the success of various industries globally. Let’s take a closer look at some of these industries and the impact of remanufactured engines:

As businesses around the world continue to expand their operations, the demand for reliable, high-performing engines that support growth and sustainability is more significant than ever. remanufactured Ford and Perkins engines can meet these demands by providing cost-effective and environmentally sustainable engine solutions that cater to the unique needs of industries across the globe.

With their widespread availability in overseas markets like Africa and mainland Europe, remanufactured Ford and Perkins engines are an attractive option for companies looking to reduce costs and support a circular economy. By investing in these engines, businesses can experience long-term benefits in terms of reduced operational expenses and improved environmental sustainability.

Remanufactured Ford and Perkins engines play a vital role in supporting the growth and success of various industries worldwide. With their numerous advantages, including cost-effectiveness, environmental sustainability, and reliable performance, these engines are an excellent investment for businesses operating in agriculture, construction, or mining on a global scale. By understanding the reconditioning process and recognising the value of these engines in diverse industries, businesses can make informed decisions to optimise their machinery and support their operations in both the UK market and abroad.

Discover the role of remanufactured Ford and Perkins engines in global industries with Timik Agricultural Ltd, your trusted engine specialists. Our team of experts is dedicated to providing top-quality remanufactured engines that meet or exceed OEM specifications, ensuring maximum performance and reliability. Visit Timik Agricultural Ltd today to learn more about our comprehensive range of engine solutions and take the first step towards powering your business to new heights of success.Trust Timik Agricultural Ltd for all your engine needs!